AS/NZS 5369: The new standard for Reverse Osmosis Water and microbial contaminants

AS/NS 4187 has been superseded by AS/NZS 5369 with a new title 'Reprocessing of reusable medical devices and other devices in health and non-health related facilities'. As far as Reverse Osmosis water quality goes the new Standard makes little or no difference. The critical section for water quality is 7.2.3.1 and consistent with the previous standard Table 7.2 summarises the specifications for water quality (see below).

What is Reverse Osmosis (RO) Water?

RO water is a highly purified water usually provided by a pressurised reverse osmosis membrane. Water is pressurised and then passes through a membrane effectively ‘sieving out’ unwanted chemicals and contaminants. The process supplies water, called ‘permeate’, that is very low in chemical and organic content. RO water quality is usually critical to it's use. AS/NZS 5369:2023 lists the target levels for the final quality of RO water in table 7.2 (see below). The American National Standard ANSI/AAMI 13959:2014 sets similar targets.

Conductivity is used as a routine measure of RO quality. 'Sieving out' the unwanted chemicals reduces the concentrations of ions that will conduct electricity. So low conductivity (mS, microsiemens) of the permeate is a good indication that the process has been successful. The low conductivity indicates a low concentration of ions (salts) that is usually critical to its uses and applications. However, conductivity does not detect organic materials, like microorganisms or endotoxin, so they are included in the standard as separate items to be periodically monitored.

For our international audience try ISO-15883-1 Washer-disinfectors for a good read! The AS/NZS standard is pretty much the same thing. Warning: microorganisms may ignore both documents.

Uses of RO water

Because of the low ion content RO permeate water is very good at picking up ions and small molecules from other sources. A classic example of this is in dialysis. Dialysis uses close contact of RO water with another fluid (often blood) through a membrane that allows ions and smaller organic molecules to diffuse to the RO water removing them from the fluid. By this process kidney dialysis units rely on RO water to remove and purify blood from individuals whose kidneys are no longer doing the job for them.

RO water is also a critical component of CSSD (Central Sterile Services Department) operations. Devices and equipment that may be re-used in invasive procedures (endoscopy) need to be cleaned and rinsed in high purity sterile water.

RO water is also important in research. High purity water that is free from contaminants and impurities is an essential in many research applications. Molecular biology (eg DNA fingerprinting) relies heavily on the purity of the chemicals used in the analyses for the integrity of results.

RO Systems

In some instances, RO water is generated on an ‘as need’ basis. More often the processed water is stored in vessels ready for use. In laboratories it is usually available ‘on tap’ from storages.

From storages the RO is distributed to outlets. The pipework in some higher risk installations is ideally stainless steel – but in most uPVC. The storage and reticulation of RO water is where problems with contamination arise.

The water provided by the RO system is of very high purity. Post-system storage and distribution can, and does, introduce contamination. Microbial contamination and subsequent endotoxin levels is a common feature of RO distribution systems. To minimise contamination attention needs to be paid to system design, materials of construction, and distribution.

Ideally the distribution system will be as short as possible and looped to allow circulation of disinfectants. Branches to outlets should be as short as possible to minimise potential for stagnation.

Outlets that are not used will stagnate. Even in very low nutrient environments bacteria, and sometimes fungi will colonise and proliferate. This is reflected in the AS/NZS /ISO requirements for routine biological testing.

In our experience the outlets are the major source of contamination in the RO supply. Infrequent use and hoses attached to outlets allow bacterial contamination that will work back through the distribution system.

So what can possibly go wrong?

Storage vessels should be fully enclosed, but easily accessible. Storages should have minimal internal surfaces / ridges that could collect debris and deposits and be able to be fully drained. Storages are best installed as close as possible to point of use to minimise stagnant water in the distribution system.

In this storage vessel there is no drain point and the balance line sits well above the bottom of the tanks. So sedimentation and biofilm growth is encouraged. What's more draining it is impossible.

Capped off pipework (white pipe on the left) creates a deadleg for sediment and biofilm. If your dead leg offends you - chop it off!

The top of this tank is not properly sealed and draws air and dust (nutrients and microorganisms) from the plant room into the storage.

Construction Materials

Stainless steel systems are probably more easily maintained and disinfected as they will cope with both chemical and thermal disinfection and don't leach nutrients. In reality due to capital cost Polypropylene / uPVC systems area more commonly installed.

Installation of materials that have not been properly handled or disinfected prior to construction is building a contamination problem into the system. Consideration should be given to the commissioning disinfection of the system and components both during and after installation. The choice of disinfection needs to be consistent and compatible with the materials installed.

Aside from these design and operational issues there are also end users. Hoses on RO outlets that are not regularly replaced or disinfected will rapidly contaminate. Even ultrapure water can't stay that way after it's run through a dirty silicone tube, or groped by a researcher.

Maintenance Requirements

The Australian Standard 5369:2023 includes routine microbial and endotoxin sampling by accredited laboratories of the permeate water (section 7.2.3.1). Microbial contamination of the water needs to be monitored. This includes endotoxin.

Endotoxin is a poison released from the dead cells of some bacteria. A result of disinfection may be an increase in endotoxin levels from killed bacteria. The bacteria decay and release the toxin. Even in low concentrations endotoxin can cause fever, nausea, muscle aches and diarrhoea. This is of critical importance in RO applications where susceptible populations can be exposed to the toxin.

Endotoxin molecules are small enough to pass through many conventional filtration devices. Managing the microbial load will reduce endotoxin loads but keeping endotoxin at safe levels may require more than just disinfection. This is particularly true when RO permeate water is held in storages where sediment can build up. When routine sampling indicates there are excursions from the guideline values it's time to disinfect. It might be a good idea to routinely disinfect to avoid unwanted system shutdowns and associated anxiety. This especially true if history tells you you already have a problem.

Maintenance staff must take care when changing components such as filters. Clean, gloved hands for changing filters and UV thimbles is just common sense (but not so common!). Be careful that the maintenance doesn't introduce bacteria into a system that's just waiting to welcome them!

Disinfection Options

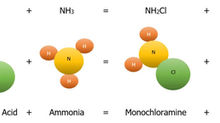

South Australian Haemodialysis Guidelines: Routine Water Testing and Reverse Osmosis Monitoring (SA Health 2013) provides information on routine monitoring and maintenance. The guidelines advise that chlorine and monochloramine concentration should be closely monitored. With regards to this we do not use chlorine as a disinfectant for RO systems. Hydrogen peroxide disinfection is more effective than chlorination in RO systems whilst leaving no harmful chemical residuals. Published literature suggests hydrogen peroxide can be successfully used to control Mycobacteria, including M. chimaera.

BWS track record

BWS have experience in the installation, commissioning, and disinfection of RO water systems. We have worked on RO systems supplying Research Facilities, CCSD, Quarantined areas, and specialised pathogen free research facilities.

Our work has previously included provision of:

· routine and specialist sampling and disinfection.

· consultancy services for dealing with problematic contamination

· new installations

· system re-design and modification

These projects have allowed us to employ a number of different intervention and disinfection strategies tailored to the specific requirements of the individual system.

Our Services

· Standard operating procedures for installation / modification of RO systems

· Routine system disinfection

· Routine sampling for water quality in Accordance with AS/NZS 4187:2014 and ISO 15883-1

· Specialist consultancy for remediation of contamination in specific applications

References

AS/NZS 5369 Reprocessing of reusable medical devices and other devices in health and non-health related facilities

(AS/NZS 4187:2014 Amendment 2 2019. Reprocessing of reusable medical devices in health service organisations. Superseded.)

ANSI/AAMI 13959:2014 Water for hemodialysis and related therapies

ISO 15883-1 2006. Washer-disinfectors. General requirements, terms and definitions and tests.

SA Health 2013. South Australian Haemodialysis Guidelines: Routine Water Testing and Reverse Osmosis Monitoring.

Thanks Richard all over it as usual